Difference explained between working on flange connections according to protocol and without protocol

In installations in the (petrochemical) industry, pipelines and fittings are connected by using flange connections. The flange is a flat ring at the end of a pipeline and ensures that no leaks occur. To be able to open or close flange connections safely, you need to follow the flange mechanic training course. Within the flange mechanic training, a distinction is made between working on flange connections according to protocol and without protocol. In this article, we explain when you need to take which course and what the differences are.

What does a flange fitter do?

A flange fitter ensures that flange connections are made between pipeline systems and appendages that you see in installations in the petrochemical industry, on- and offshore oil and gas industry and the maritime sector. Because opening and closing flange connections involves precise work that can have major consequences if it is not carried out correctly, this work is often done according to a set protocol.

What does working on flange connections according to protocol mean?

Leaky flange connections can lead to delays and (sometimes very high) costs in the start-up phase of a refinery or chemical plant. To prevent this, protocols have been drawn up that describe exactly how flange connections must be opened and closed in a correct and controlled manner. Every refinery uses its own procedures and protocols. It is therefore important to always enquire about the applicable regulations in advance.

Which types of flange connections require working according to protocol and which do not?

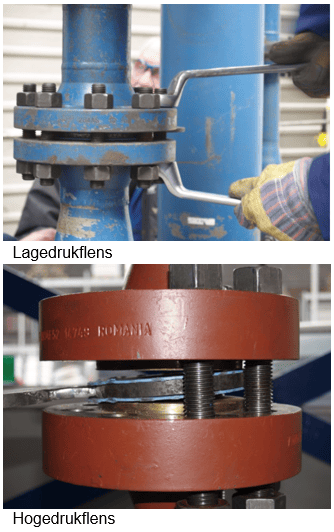

The flange mechanic course was created in order to improve the information provided to mechanics. In the past, working on flange connections received relatively little attention in the field, in contrast to, for example, welding on flanges and pipes. The lack of information about working safely on flange connections resulted in unnecessary leaks. Working on Flange Connections has been developed as a basic course to cover simple work on flange connections with standard hand tools. Because some systems have very high requirements, they often have to be secured with special equipment and the aforementioned special procedures apply. Whether you need to follow the training course working on flange connections according to protocol depends on the type of flanges you come into contact with in practice. There are low-pressure flanges and high-pressure flanges. The flange technician training for working on flange connections without protocol only applies when you work with low-pressure flanges.

Difference between low and high pressure flanges

The name says it all, the difference between low and high pressure flanges is that low pressure flanges are under lower pressure. In technical terms, this means that low-pressure flanges can have a maximum working pressure of 50 bar. For high-pressure flanges this may rise to 400 bar working pressure. For flanges that are subjected to such high pressure, it is therefore extra important that they are mounted correctly in order to prevent leaks.

Difference between the course Working on flange connections according to protocol and working without protocol

During the protocol training on flange connections, candidates learn how to apply controlled pressure to the gasket. The gasket ensures a good seal of the flange connection. During the training course working on flange connections according to protocol, the pressure on the gasket is gradually increased and accurate measurements are taken in the meantime. In the course working on flange connections not according to protocol, this is not part of the training. During this training the candidates learn how to fasten a gasket using ring spanners. In the course working on flange connections according to protocol, assembly is done using controlled torque spanners.

Training advice: working on flange connections according to protocol

At DELTA Safety Training we always recommend following the training working on flange connections according to protocol. In practice, we see that clients hardly ever ask for a training course on working on flange connections, but rather for a training course on working on flange connections according to protocol. Clients who work in the petrochemical industry require that mechanics have successfully completed the training on working on flange connections according to protocol. But also when technicians do not work in the petrochemical industry, it is advisable to follow the training on working on flange connections according to protocol. After completing the training course working on flange connections according to protocol, you will be more broadly deployable, while the investment for following both courses is the same. When you have a certificate for working on flange connections according to protocol, you can also work on low-pressure flanges, while this is not the case the other way around. For both trainings you can choose for a DELTA or a SOG certificate.

Would you like personal advice about the flange mechanic course? Our colleagues will be happy to help you! Fill in the form below and we will contact you personally.